|

|

Laser

Hobbyists - Laser Construction

Many people have expressed an interest

in building their own lasers, particularly green DPSS lasers. The

first step in building a 532 nm laser is to produce the

necessary IR laser beam for frequency doubling. This

article on building an IR laser pump cavity was

contributed by Bob, the resident solid-state laser guru on

alt.lasers.

Pump

Cavity

Photo note: In order to provide as

much detail as possible, very large photographs were

provided to illustrate this article. They are too

big to post on this web page so smaller versions are shown

here. There is a link at the bottom of the page that

will allow you to download a .zip file archive of the

original, large format, high resolution photographs.

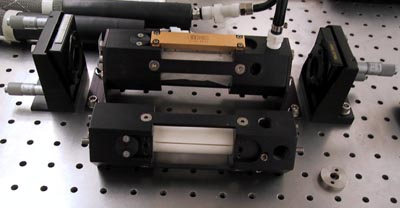

img_0633

In the foreground a 3 fold symmetry pump assembly is visible. in the background a single

sided pump housing is seen. In the 3 sided pump housing, no pump diodes are present.

The line in the white ceramic on this housing is a glass waveguide.

The pump diodes 'look' at this waveguide, which serves to transmit light through the walls of a ceramic defuse

reflector. Clearly visible on either sides of this

waveguide (on the end blocks of the pump housing), are rubber

O-rings that mate up to the cooling path of the diodes.

Cooling water comes in and is split into three separate paths for the pump diode

assemblies, then is directed back the other direction to cool the

laser rod.

In a configuration such as this, a thermal switch should be placed on the back of each diode heat sink, such that the power

supply will turn off in the unlikely event that cooling water flow is

obstructed in any one of the diode heatsinks. In the single sided illumination housing this is obviously not an

issue, and water flow integrity can be monitored by overall water flow through pump housing.

The set screws and rounded anodized aluminum disk seen in the three sided pump housing

are portions of the water cooling channels machined into the housing.

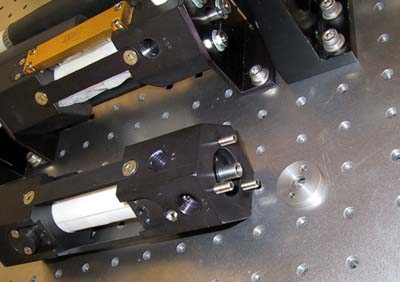

img_0632

In this photo, the rod holder and outer O-ring seal can be seen.

The rod holder used is designed to keep the faces of the rod dry by small

Teflon O-rings. The outer O-ring seal defines the water flow path for the rod, along with the inner

O-ring seen in the next photo.

img_0634

In this photo, a close up of the inner O-ring seal is seen.

The stainless disk seen at the end of the ceramic reflector compresses the

O-ring around the glass flow tube against the end block of the pump housing.

This defines the water flow path for the rod.

The ceramic diffuse reflector is also seen in this photo.

For the diffuse reflector to be effective, a minimum wall thickness of 7 to 8 mm should be used.

Also seen is the waveguide that couples light into the inside of the pump cavity where the

YAG rod normally resides

img_0636

One of the most important portions of the pump housing is this alignment pin.

A notch in the end stainless steel ring is clearly visible.

This notch continues to the ceramic reflector, although it is not clearly

visible in the photo. This notch provides for indexing the rotation

of the diffuse reflector, to keep it in the correct relationship to the pump diodes.

Also seen in this photo is a groove provided to allow a seat for the inner

O-ring. The additional grooves provide a 'step' in the inside diameter of the housing that hold the rod holder.

The fit of this rod is very snug near the end of the pump housing block, where the

outer O-ring is located. This ensures a good mechanical support for the rod.

The inside diameter then increases in steps inside the pump block

to allow for a sufficient water flow path to cool the rod.

A note on the construction of the slit in the diffuse reflector for the waveguides:

As can be seen in this photo, the slit where the waveguide

resides is somewhat longer than the waveguide itself.

The ceramic was clamped down, while the 1.05 mm thick slit was cut in it with a 1"

diameter diamond wheel saw. As the saw can not cut a square face, the slit was

purposely cut a bit short for the waveguide on the inside

diameter of the diffuse reflector; and a bit long for the waveguide

on the outside diameter of the diffuse reflector. A narrow file, or a piece of sand paper folded over a small

stainless steel ruler was then used to lengthen the slit in the

outside diameter of the cylinder.

Once the slit is enlarged to allow the waveguide to be

freely inserted, the small overspill on the outside

diameter allows for a convenient pocket for a highly viscous

UV cured optical cement to grab the edges of the waveguide.

The use of a very viscous cement and these small overspill 'pockets' is rather

important; if a less viscous cement is used, or if the waveguide is glued in by the optical faces, the index

of most cements will not allow TIR [Total Internal

Reflection] to keep the pump light in the waveguide thus reducing

efficiency. In some cases, enough power is

transmitted to fracture the ceramic due to excess heat dissipation.

It is also important to note that the glass waveguide must fit freely into this slot. if the fit is

difficult or needs ANY encouragement, you will most likely

have scratched the waveguide, reducing it's efficiency.

If the slot is opened up too far, there will be unacceptable slop in the position of the

waveguide. For this reason it is advisable to get an extra waveguide made as a dummy that can be used

to gauge the proper thickness of the slot.

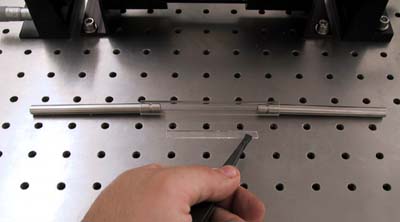

img_0638

Here we see the internal flow tube, rod mounts and waveguide,

separated from the pump chamber. The waveguide is being held in position as it would be 'looking' at the rod in the center of the flow

tube.

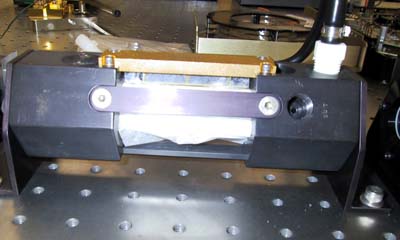

img_0639

Here we see a finished cavity with the ceramic diffuse

reflector and it's waveguide. The waveguide is wrapped

in lens paper to protect it from dust etc. However the location of the pump diode array looking at

the waveguide in the diffuse reflector can be seen.

img_0640

Pump assembly for 3 sided pump cavity... note the alignment of the diode

bars. The bars must be aligned to a tolerance of a fraction of a

millimeter. Each pump diode assembly looks at it's own waveguide, only a millimeter thick. by the time the pump light hits

the waveguide, it's width is several hundred microns, allowing for a

positional error of the centerline of the pump assembly to be no more than a few

hundred microns on either side of the centerline of the

waveguide.

This is the most critical specification of the entire assembly.

Gross misalignment will cause light to spill past the waveguide, heating the

ceramic reflector, possibly to the point of fracture.

Sources for materials

-

The ceramic used is called Maycor.

Other machineable ceramics by the trade name

Spectralon is also available, however I strongly prefer

Maycor. This material is available in any size and

shape you could imagine from Ceramic Products Inc,

Palisades park, NJ, (201) 947-0336

-

The rod holder used is an industry standard holder used in may lasers. the rod is 4mm in diameter.

Aa holder from a Control Laser, Laser Applications,

Lee Laser, or the like would suffice. If one can

not be scrounged, then buy a 4mm rod holder from TJ

Sales, Sanford Florida, (800) 561-6164

-

The glass flowtube used in this particular head has an

inside diameter 1 mm larger than the outside diameter of the rod holder

and a wall thickness of 1mm. I do not list specific dimensions

in this case, because there are some minor differences

in 4mm rod holders that might require one to use a different

id tube.

Normally Pyrex can be used, and is very cheap HOWEVER a 1mm

thickness of Pyrex has only a transmission of about 92% for

808nm light. if you want to build this on the cheap or you want to build a prototype for the

least amount of money, use Pyrex. TJ Sales listed above can provide flowtubes to your specified id / od

and length requirements. If you would like higher

efficiency, use a flow tube made out of bk-7.

-

The rod used was a .9% Nd rod. this is not the optimal dopant concentration for a diode pumped laser,

nor for a diode pumped laser with such an inhomogeneous

pump profile as a single sided cavity. However, since the light from the waveguide is highly

divergent, and mostly not absorbed in the first pass at the rod, the diffuse reflector does a good job of

homogenizing the pump light distribution.

Most YAG you will find on the market is between .9% and 1.2% Nd... a

knowledgeable surplus dealer may be able to identify the concentration based on the laser the rod was

used in, or if you are lucky by it's original packing.

The rod used in this case was 4mm diameter by 80mm in

length. YAG is not self absorbing, so there is no reason not to leave yourself with

a lot of overspill on the ends... it makes assembling things

in the rod holders much simpler.

-

The glass waveguide I used was a 1mm thick, 8mm deep, and 68 mm long piece of bk7. the entrance and

exit faces do not need to be anti-reflection coated, but it naturally will lead to a

more efficient laser if they are. Any optic house can fabricate

these waveguides. I had VLOC of Port Richey, Florida

(727) 375-8562 fabricate these waveguides (and the bk7 flowtube).

If you use someone else, expect a price of about $100

US$ ea for a quantity of a few.

-

The optical adhesive used is Norland NOA63

available from Thorlabs at (973) 579-7227

Defenses

between this design and a highly efficient one

As mentioned before, this design is every bit as good as

an homogenizing pump light, even when using single sided

illumination. If you want the best results, you really should use something like

0.6%Nd. Most optics houses don't stock this material.

At the time of this writing, VLOC had some 0.6%ND material

sitting on the shelf from a previous order (quite possibly mine :) ).

A proper rod might cost you a few hundred dollars as opposed to

$100 US$ for a surplus rod.

In this design, the inside diameter of the diffuse reflector is simply fine ground and honed at the local machine

shop. This does not provide the most efficient surface on the inside of the pump chamber.

If you are familiar with amateur telescope finishing, then you may be able to come up with a way of polishing

the inside diameter of this tube. A steel rod in a drill, with a polishing

compound soaked felt will work, but takes patience... when a good polish is

achieved Maycor will have a very glassy look to it.

The better the polish the more efficient a diffuse reflector you

have.

If you do not want to use a waveguide or flow tube that is

anti-reflection coated, this is fine, however, keep in mind that

paying for anti-reflection coatings is just about the same as getting 20% more

pump diode light... If you have the same optics house make your waveguides and flowtube, then ask them if they will hold the

pieces till they do an 808 nM anti-reflection coating run for another

customer; that way you don't have to pay for coating runs for your 3 or 4 little pieces of

glass. For an efficient coating, at least 3 runs are needed... 3 runs to get the entire

diameter of the flow tube, and 2 of the runs for each side

of the waveguide (entrance and exit faces). If you have an

optics house just do the coating runs for your parts, you may expect to pay upwards of

$1500 to $2000 US$ - if you get lucky and find someone who will deal

with you, you might get your stuff coated for a few hundred

bucks!

Finally, the waveguides in my more advanced design

cavities are a little bit more exotic. The waveguide

is not a constant 1mm thick, but tapers from 1mm at the entrance face to 300 microns at the exit.

This waveguide is much more expensive, and requires a more exotic

machining process to be used on the diffuse reflector to properly hold the tapered

glass waveguide in place. Such an improvement is beyond the scope

of this home build pump chamber.

A single sided pump cavity with a short resonator and

240 watts of pump diode power yields about 85w of 1064nm in a

acceptably homogenous high order mode beam. Power output will drop to about

50 watts using a Pyrex flowtube and non anti-reflection coated surfaces.

Coming

next...

Turning this into a cheap green laser...

PHOTOS: Download the detailed

high resolution photos - PumpCavity.zip

(3,063 KB)

Most

of the information and ideas in the Hobby Archives have been contributed

by hobbyists and experimenters. If you have any comments or ideas to

share, please contact us by E-mail.

DISCLAIMER:

Some of the information in the Backstage area is provided by the persons or

companies named on the relevant page(s). Laser F/X does NOT endorse or

recommend any products/services and is NOT responsible for the technical

accuracy of the information provided. We provide this information as a

service to laserists using the Backstage area.

[ Introduction

| Hobby

Archives | Hobby

FAQ | Laser

Construction ]

|