|

How

Laser Shows Work - Laser and Exciter

The laser generates the thin beam of intense

light that is controlled and manipulated in the projector to produce the

effects seen by the show spectators.

|

|

|

A high power,

air-cooled copper vapour laser

- Photo courtesy of Spectronika

|

What makes

the light from lasers special?

The light from lasers differs

from ordinary light in several important aspects. Ordinary light from

a light bulb travels randomly in all directions (unless the bulb is equipped

with an integral reflector that directs the light). The light is thus

incoherent. Even when incoherent light is directed with a reflector, it

still spreads rapidly.

The light from a laser is

temporary and spatially coherent. This means that all of the wave-fronts

of light are lined up in time and space (see diagrams). The waves of

light go up and down in sync, and travel in the same direction.

Coherent light spreads less

than other types of light. For example the beam of a tightly focused flashlight

would spread between 2 degrees and 5 degrees over a 3 meter (10 ft) throw

distance. The sides of a laser beam are almost parallel but the light

still spreads slightly. This spread is called divergence and is measured

in milliradians (mrad). If a laser has a specified divergence of 5 mrad,

then in the above example with a 3 meter throw (10 ft), a laser beam will

spread only about 3/20 of a degree.

How do lasers

make light?

This is a simplified explanation of the

process of stimulated emission. If you are interested in more detailed

information about this subject, you should consult a science or physics

book.

Let us take the HeNe laser

as an example. If a glass tube were filled with a mixture of helium and

neon gas; and an electrical current were applied to the electrodes, the

gas would emit light energy. This glowing gas is referred to as a plasma.

You are already familiar with this glowing gas in the form of the neon

signs you see at your favorite restaurants. We now have a neon tube but

not a laser so let's take a closer look at how the laser's light is produced.

Under normal conditions the electrons in a gas atom orbit at a fixed distance

and pattern around the nucleus; this is the ground state or most stable

configuration of the atom. When an electrical charge travels through the

gas in the tube (energy is pumped into the gas), it excites or stimulates

the atoms. Some of the electrons absorb this energy by jumping up to the

next highest orbit.

This configuration is unstable. The electron wants to return to its regular

orbit, the ground state. As the excited (stimulated) atoms in the gas

relax back to the ground state, some of the energy that excited the electron(s)

is emitted (released) in the form of random photons of light (see

diagram below).

This is called spontaneous

emission. This is how a neon sign (or other gas discharge light such

as a mercury vapour lamp) produces light. The photons travel rapidly

in all directions. They are visible along the length of the neon tube

or radiate outward from the light source. The spontaneous emission is

not enough to cause lasing action.

Lasers are very different from neon tubes in that they amplify the glowing

effect via stimulated emission. Stimulated emission can only occur when

there is a "population inversion" in the energy state of the

lasing medium (in this case gas).

Laser tubes are designed in a long narrow configuration with a central

bore. At either end of the bore there are mirrors. These mirrors must

be held in precise alignment for the laser to work properly. In most HeNe lasers the mirrors are permanently attached or sealed onto

the ends of the tube -- sometimes referred to as hard seal technology.

In higher power lasers, the mirrors are usually not mounted on the ends

of the tube itself, but on an external resonator that forms part of

the laser frame. This allows for changing the mirror optics or adding

a littrow prism if a specific output wavelength (colour) is required.

The mirrors must be perfectly aligned and parallel so that the emissions from the

gas in the tube will be amplified.

Some of the photons of light

randomly emitted by the relaxing gas atoms will be traveling parallel

to the bore (centre) of the laser tube. These photons will strike the

mirror (high reflector) at the end of the tube and will be reflected back

through the excited gas (plasma). When the photons traveling parallel

to the bore are reflected from the mirrors, they oscillate back and forth

between the mirrors.

|

|

| An air-cooled laser tube with cooling fins - the

connections for the cathode/filament are visible on the right -

Photo courtesy of Laser

Physics Inc. |

In their travels through

the plasma, some photons strike other atoms that are in the excited state.

The excited atoms are stimulated into relaxing to the ground state and

releasing their duplicate photons.

The groups of photons travel back and forth through the lasing medium

(gas) reflecting from the mirrors at either end. They build up sufficient

energy to overcome optical losses, then lasing begins. All of the above

activities take place almost instantaneously (at the speed of light) when

the tube is started. The mirrors form an optical "amplifier"

allowing for the amplification and stimulation of the lasing medium (gas)

in the cavity (plasm tube) to produce light (photons).

If the mirrors were both totally reflective, the light would remain trapped

inside the tube. In fact the high reflector is coated to 99.9% reflectivity

(it should be 100% but nothing in life is perfect) so as to reflect the

maximum amount of light. At the other end of the tube, the output coupler

is coated between 90% and 97% reflectivity (semi-transparent mirror).

Thus between 3% and 10% of the light in the tube is allowed to "leak"

out as the laser beam which you see in light shows.

This "leaking" light would drain all of the energy from the

plasma if it were not for the electrical power that is continuously applied

to the tube. The electrical power keeps the plasma energised (ionised)

and allows the laser to produce light continuously. Some types of lasers

do have a cycle where energy is pumped into the lasing medium in pulses,

then released in a short burst of laser energy. This type of laser is

referred to as a pulsed laser and usually produces very high power levels.

Lasers in

light shows

There

are three main types of lasers used in laser light show

applications:

-

Ion (gas) lasers such as Argon

(Ar), Krypton (Kr) or "Mixed Gas" lasers (Ar/Kr)

-

Diode Pumped Solid State Lasers

(DPSS)

-

Diode lasers

The

laser most often used in

professional light shows and displays is the Argon (Ar) laser. The argon

laser gives a cyan coloured beam that can be split into blue and green

beams using a yellow dichro or a prism. A Krypton (Kr) laser can

be configured to produce a number of different colours or red only.

In some laser shows, an Argon and a Krypton laser are used as a

"tandem pair" where the beams are combined to produce a

"white" beam.

Full colour laser shows usually use "white light" lasers that contain a mixture of argon (Ar)

and Krypton (Kr) gases in the laser tube and produces red, (sometimes yellow) green and blue

from the same plasma tube. This is simpler and more convenient that

using a tandem pair of Ar and Kr lasers.

|

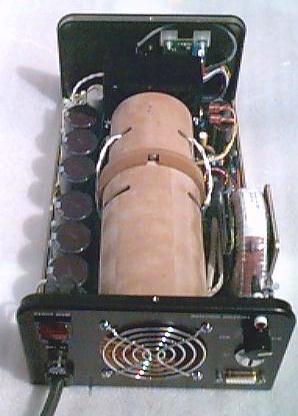

Interior of an air-cooled

argon laser

On the right is a photograph of a modern air-cooled

argon laser with an integrated power supply with the top removed

so you can see the internal components.

The laser tube is inside the reddish air-shroud which is used to

channel the cooling air across the heatsink fins on the tube before

it is blown out of the laser by the fan on the back.

On the right towards the back is the torrodial power transformer.

On the left is a bank of capacitors that forms part of the power

supply (most of which is not visible as it is located on a board under the laser tube).

At the back left, you can see the power cord, fuse and switch. On

the back right the key interlock (for safety) and the remote control

connector are visible.

This laser outputs 100Mw (1/10 of a watt) from a compact package

that weighs about 7 Kg (15Lbs) and operates from 110 VAC.

|

Photo courtesy of Laser Physics Inc.

|

The most common type of gas laser you

will see is the Helium Neon (He-HeNe) laser which produces a low power

red beam and is used in hobby and consumer laser shows and even in some

supermarket check-out scanners. The HeNe is rapidly being replaced

by red diode lasers (the type used in laser pointers) due to their compact

size, low power requirements, long life and the low cost of laser diodes.

Other common types of lasers used are Krypton (Kr) and mixed gas lasers

that are usually referred to as "white light" lasers as they

produce a pinkish white beam that contains a number of colours. High power

solid state YAG lasers producing intense 532 nm green beams are also used,

especially for outdoor shows. Copper Vapour lasers produce emerald green

and gold beams.

The laser is usually mounted on a rail

or base plate so that it will be in a fixed and rigid relationship with

the projector. If there is any vibration between the laser and projector,

it will affect the alignment within the projector and the alignment between

the projector and distant effects such as bounce mirrors.

Exciter

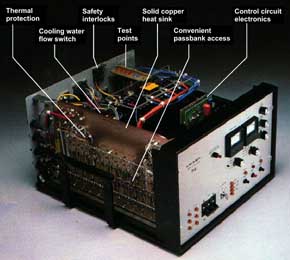

The exciter is the power supply for the

laser that takes

the multi-phase high voltage AC line power and converts it into the DC voltages

and control signals that are needed to drive the plasma tube inside the laser head.

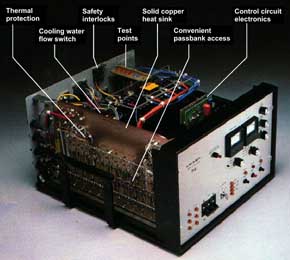

Click Here

to see the full size image (opens in a new tab) - Photo courtesy of Lexel Laser

Lasers can

be air-cooled or water cooled - the photo above shows an exciter for a

water cooled ion laser. The exciter usually contains electronic control circuits

to adjust the current to the laser tube, light feedback regulation and circuits

to

control the start-up and shut down sequencing of the laser system. The

exciter pictured above has a large, water cooled, copper "cold

plate" (heatsink on the left) where the main power transistors are

mounted (the passbank). Water passes through tubes in the cold plate

to keep the power transistors cool. Water cooled exciters also typically contain flow detection

devices and temperature interlocks to prevent the operation of the laser if there is

insufficient water flow, or if the temperature of the system is too high.

Solid

State Lasers

Recently, Solid State Lasers,

also called Diode Pumped Solid State (DPSS) lasers, have become available.

Rather than using a gas filled glass tube, these lasers use a

laser diode to pump a crystal or a series of crystals. The

general principals of producing light by spontaneous emission

discussed above are used, but rather then exciting atoms of gas,

atoms in the crystal are excited to produce light. The

advantages of solid state lasers are that they are smaller, light

weight, more rugged and reliable, have blanking capability built

in reducing the need for external components, and use less

electrical energy.

Inside

a DPSS Laser

Below is a simplified diagram of a green (532 nM) DPSS

laser - other colours can be generated by using different crystals

and pump diodes. There is a great deal more detail and

complexity involved in the design and manufacture of these lasers

but this diagram will suffice to explain the general principals.

-

A - A diode driver circuit is required

to provide the current form the power supply (not shown) to

the pump diode. This power supply circuit has to be very precise as

IR diodes are very sensitive and easily destroyed by power

spikes or static discharges. For simplicity, the rest of

the electronics involved in the laser are not shown.

-

B - Powering a DPSS laser is an

infra-red (IR) laser diode, the pump diode, emitting at 808 nM. This frequency is in the near infrared so is faintly

visible to the eye as a very dim, deep red light. Just

as with any laser, the light emitted by the diode is dangerous

to the eye.

-

C - In order to keep the output of the pump diode at

exactly 808 nM, it is mounted on a Thermoelectric Cooler (TEC)

as the output frequency of diode lasers is temperature

dependent.

The TEC is an electronic device which transports heat from one

side to another when an electric current is passed through

it. It can be use to either cool or heat a device.

In a DPSS laser, the pump diode is attached to the

"cold" side while the "hot" side is

attached to a heat sink to dissipate the heat that is carried

away from the diode through the TEC. It can be simply

controlled by sensing the temperature of the pump diode and

then using an electronic circuit to regulate the TEC so as to

keep the pump diode at the correct temperature such that the

diode frequency is exactly 808 nM.

-

D - The beam output by the pump diode

is not the circular beam that we are used to seeing from an

ion laser thus complex beam shaping optics must be used. The

pump diode has a "fast" axis in which the beam

diverges widely, and a "slow" axis in which the beam

diverges far less. The beam shaping optics are used to

make the beam from the pump diode as round as possible.

It is usually not possible to make a perfectly round beam so

most DPSS lasers have a slightly elliptical beam where the

beam can be as much as 2X bigger in one axis in some of the

cheaper lasers.

-

E - A second harmonic of the 808 nM

pump diode light is generated by an ND:YVO4 crystal.

This converts the light from 808 nM to 1064 nM with is also IR

light but is not visible to the eye.

-

F - For optimal performance, the

ND:YVO4 crystal must be "temperature tuned" so it is

also mounted on a TEC cooler with a controller.

-

G - The 1064 nM light is sent to a KTP

crystal which frequency doubles the Infra Red to 532 nM green light.

-

H - The KTP crystal must be

"temperature tuned" so it is also mounted on a TEC

cooler.

-

I - Just as in a traditional ion laser,

an output coupler is used to form the laser resonator.

-

J - The 532 nM (green) beam emitted from the

KTP is very tiny and divergent. Beam shaping optics are

used to expand and coliminate the beam to form the final laser

beam output.

-

K - The final optic is usually an IR

blocking filter. This passes the 532 nm green laser beam

and blocks any of the IR light from inside the laser that

would otherwise be emitted. This is a safety feature to

prevent the emission of invisible IR light.

For the technically inclined,

we offer RGB

Lasers for laser projection displays A detailed

paper (.pdf format) which discuss the design and development of

the first, high power, all solid state RGB laser system for image

projection systems by JENOPTIK Laser, Optik, Systeme GmbH.

Diode

Lasers

Diode lasers are generally only

used in very low power laser equipment since they are not

available in high power outputs and generally have poor beam

quality. Diode lasers are similar in structure and operation

to an LED as they are a solid state device that emits light when

suitable power is applied. The internal construction of a

laser diode is different from an LED and they may contain internal

or external optics to focus and/or collimate the beam. The

most common use of laser diodes is ion laser pointers.

[ Laser

and exciter | Projector

| Scanners | Control

console | Graphics system

| Outboard Equipment ]

|