|

Laser

Show Systems - System Design

Compact

Programming System

By L. Michael Roberts

Abstract

The design of a practical, compact 30K laser graphics

programming system based on a modulatable red diode laser and 6800HP

scanners is described. A secondary design criteria was to allow the

use of the programming projector with an external

laser source.

Introduction

For programming laser graphics and animations, it is often

impractical and can be expensive to set-up a whitelight laser. It is

not always necessary to see the images in colours as during digitizing and

programming, the quality of the image, sharp corners, joined lines and the

overall 'look' of the image are more important considerations. The

design objective for this system was to create a programming projector based

on a diode laser, but with sufficient flexibility that it could be used with

other lasers of various types as well.

Design

Constraints

The major constraints in terms of size were; all the

components that had to fit into the case [no outboard electronics], and the

case had to be an 'off the shelf' enclosure to save the expense of having a

custom enclosure manufactured.

The single largest component of the system was the +/- 24 VDC regulated

power supply needed for the scanners. The second largest component was

the scan amps themselves with all other components having much smaller

footprints.

The input connector chosen was an DB25 ILDA standard connector so as to have

maximum compatibility with a variety of graphics and control systems.

|

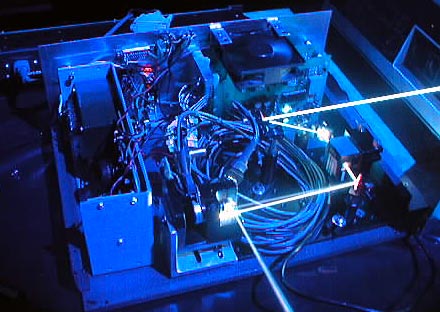

The completed

projector in use with an external whitelight

laser and PCAOM

|

Construction

The enclosure chosen was an 'off the shelf' electronics

cabinet available from a local electronics store. The cabinet was made

of thin formed steel with aluminum front and back panels and measured 16 X

12 X 6 inches [40.5 X 30.5 X 15.5 cm].

The cabinet was not sufficiently rigid to mount optical components in a

stable relationship to one another. A 1/4 inch [.7 cm] baseplate with

the same depth as the enclosure [12" - 30.5 cm] and extending 1.75

inches [4.5 cm] beyond one end of the cabinet was attached to the bottom of

the cabinet. This provided a firm foundation for mounting the power

supply and other components and also provided rigidity for the optics.

In order to provide maximum flexibility and configurability in mounting the

optics, a 'mini' optics plate measuring 10 X 6 inches [25.5 X 15.4 cm] with

holes tapped 1/4-20 on a 1 X 1 inch [2.5 X 2.5 cm] grid was mounted to the

font right quadrant of the projector. This would allow for the

mounting of the diode laser, scanners, steering mirrors and an optional

PCAOM cell if full colour operation with an external laser was desired [the

PCAOM driver would have to be in an outboard enclosure in this

configuration].

The power supply was bolted to the aluminum baseplate through the cabinet at

the far left hand end of the enclosure. In order to save space, a

small PSU board with caps and +5 VDC regulator was mounted inside the 24 VDC

power supply and fed from the positive rail to provide power to the red

diode laser. The scan amps were mounted at the back right hand side of the

cabinet so that the trimmer controls faced outwards and were easily accessible

with the cover off.

The CTI 6800Hp scanners were installed on the standard Cambridge Technology

heatsink. This in turn was mounted on a black anodized L bracket made

of 1/4 inch [.7 cm] aluminum. Heat transfer compound was used at the

junction of the CTI scanner heatsink and the L bracket to insure good

thermal transfer. The L bracket was drilled and tapped with the hole

on the optical axis of the input beam. This allows the entire scanner set on it's

L bracket to be adjusted for vertical image placement. This assembly

was attached with a single screw to another L bracket with slots in the base

designed to pass 1/4-20 screws so that it could be optimally placed and

adjusted into the laser beam.

Components

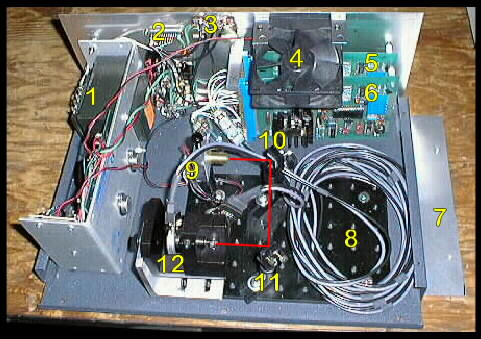

The photo below shows the completed projector with the

components numbered and the laser path drawn in red for clarity.

The assembled programming projector shown

with the top cover off.

-

1/ The regulated +/- 24 VDC power supply

for the scanners. At the front left side you can see the top of

the circuit board for the +5 VDC laser power supply.

-

2/ ILDA format DB25 input connector on the

back panel for the scanning signals

-

3/ Input gain control pots to adjust mage

size

-

4/ Cooling fan for the scan amps.

This is a 24VDC fan which was connected to the negative side of the

supply to balance the load as the laser is powered from the positive

side of the supply.

-

5 & 6/ A pair of single channel DLT

9370 scan amplifiers from new Method Lasers. Note that the adjustment

trimmers face outwards for tuning the system.

-

7/ The extension of the baseplate with two

tapped 1/4-20 holes. This is provided so that the projector can be used

with outboard lasers by sending the beam through a hole in the side of

the cabinet.

-

8/ The mini optics plate tapped with 1/4-20

on a 1 X 1" grid for mounting the optical components - there is sufficient

additional space on the right side of the plate for input steering

mirrors and a PCAOM cell if desired.

-

9/ A Spectronika optics post and post

holder mount holding a 30 mW modulatable red laser diode [brass barrel]

from New Method Lasers which is powered from the +5 VDC PSU. The

modulation input is connected via a diode array to the ILDA DB25

connector - the diode array combines all of the 6 colours into one

signal.

-

10 & 11/ A pair of Spectronika OM3/4 optics

mounts with post and post holders. These hold mirrors to steer the

laser beam into the scanners.

-

12/ the CTI 6800Hp scanners mounted on a standard

CTI heatsink and then on an L bracket to allow for vertical adjustment -

the adjustment screw can be seen on the left. That assemble is mounted

on a secondary L bracket with slots for adjustment into the laser beam.

[The large coil of cable to the right is the standard length of cables

as provided by CTI. the author left them intact to avoid cable

capacitance issues.]

Acknowledgments

The author would like to thank Bob Ash of New Method

Lasers

who provided the +/- 24 VDC PSU, modulatable red diode laser and the DLT

scan amps, and also provided technical assistance in tuning the system.

DISCLAIMER:

Some of the information in the Backstage area is provided by the persons or

companies named on the relevant page(s). Laser F/X does NOT endorse or

recommend any products/services and is NOT responsible for the technical

accuracy of the information provided. We provide this information as a

service to laserists using the Backstage area.

[

Introduction - System

Design - Scanning Systems

- Support

Equipment - Laser

Graphics - Show

Production - Pinouts ]

|