|

Laser

Show Systems - Scanning Systems

HOW TO TUNE

TO THE ILDA TEST PATTERN

By Bill Benner and Patrick Murphy, Pangolin Laser Software

Note: The information reproduced here was originally published in

the Winter 1994 edition of Laser Effects The Light Show Quarterly and is

reproduced here by permission.

The ILDA test pattern was adopted on 24 June 1992. At the date of

publication in Laser Effects, ILDA has not yet published any instructions

for using the test pattern. There are still elements of the test pattern

which are undocumented anywhere. To help fill the information gap, Laser

Effects prevailed upon Pangolin Laser Software to write this article. These

are not official instructions -- they reflect Pangolin's experience only.

This article is for intermediate and advanced laser display personnel. It

assumes you have experience with scanner tuning procedures in general, and

your system in particular. Because all scanner amps are different, the

article cannot give specific information on which way to turn controls, etc.

|

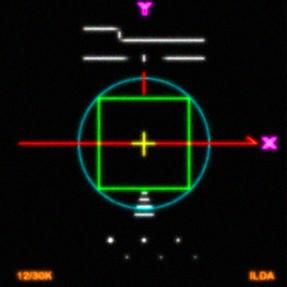

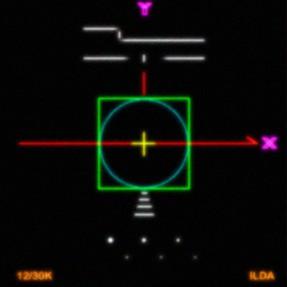

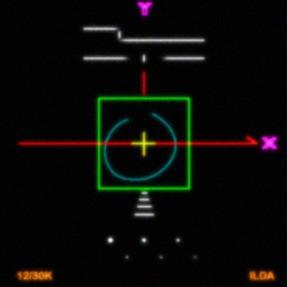

This is a drawing of how the ILDA test

pattern should look when properly tuned. Although it says "12K"

at the lower left, you tune when it is running at one of the two ILDA

standard speeds: either 12,000 (12K) of 30,000 (30K) points per second.

|

Picking Your Tuning Speed

The first consideration is what speed you wish to use in

tuning your particular scanning system. Most closed-loop scanner amps can

run at 12K. This speed can also be reached by open-loop scanners using

"acceleration" feedback scanner amps.

The 30K speed is for CT-6800 scanners and for General Scanning G-120

scanners being driven with "turbo" scanner amp designs.

This pattern will not work with some older scanner amps designed for

small-step response only. For these amps, software never permits a large

jump between points in an image. Such amps may blow fuses or may be damaged.

The ILDA test pattern is designed for systems were points can jump any

distance.

Scan Size (angle)

The second consideration in tuning is the scan size. The

absolute maximum scan size is the rated scan angle limit. In the case of

G-120 scanners, at 12,000 Points Per Second (PPS) the limit is 40 degrees

peak-to-peak. For G-138 scanners, the nominal limit is 76 degrees.

Normally your maximum scan size will be below this limit. For example, in an

auditorium the screen may be far away, so you can scan only 20 degrees. When

tuning for this venue, output the ILDA test pattern so that the outer square

is scanning at 20 degrees before starting the tuning procedure.

However, in many cases you want the maximum scan angle. Tune to about 10%

under this, to give yourself a margin of safety. For G-120 scanners, this is

roughly 35 degrees at 12K PPS.

If you are tuning faster, the maximum scan angle is reduced. For both

CT-6800 and G-120 scanners, the limit is about 25 degrees at 30K PPS. Once

you tune to a certain safe angle, scanner response is then flat up to that

angle. This means that a full-size image will not distort when it gets

smaller (on a zoom-out, for example). However, the image may distort if it

is enlarged past the maximum tuning size.

For this reason, tune to the largest safe angle that you'll encounter at

your studio or show site.

There is one time when you do not start tuning at the at

the largest safe angle. This is when the scanner amps are in an unknown

state. In such a case, begin with a small image. Tune to get is "in the

ballpark" before increasing the size.

There are two sets of test in the ILDA Test Pattern. The "A" set

is for scanner alignment, and the "B" set is for blanking

alignment.

"A"

tests: Scanner alignment

A1: Correct scanner speed. The circle should be the

same size (width and height) as the square. It should touch the midpoint of

each side of the square, as shown.

This is the most important requirement for speed

matching. If the circle is smaller than the square, then the scanners not

being driven as hard as they should be. Increase servo a bit, then increase

damping to compensate for any over or undershoot (see above or glossary for

an explanation of gain. offset, servo and damping).

On most scanner amps, the image size will also change, so adjust gain to

keep the same image size. Continue increasing servo and adjusting damping

(an gain as needed) until the circle just touches the square's sides.

If the circle is larger, then the scanners are being driven too

"hot" beyond the ILDA spec. Decrease servo and adjust damping (and

gain if required) to match the circle to the square.

You will probably find that the circle is a bit sensitive. This is actually

good -- if it wasn't sensitive then there would be no point in tuning to it!

You can be assured that if your scanners show the test pattern properly,

then other scanners tuned using the same speed will match your scanners.

A2: Correct damping. Corners of the square should be

sharp, with no overshoot or undershoot.

This is the most important requirement for good

looking images. The damping control is the primary control for setting

corners. As you tune, adjust the scanner amp damping back and forth. Watch

the corners of the square go to far (overshoot) or not far enough

(undershoot). You need to over then under tune to get a feel for when the

corners are correct. The procedure is similar to tuning an analogue radio

receiver, where you go back and forth until you find the clearest signal.

When adjusting damping, it is easiest to switch to a separate frame with a

7/8 size quadrature square. Don't use a full-size quad square, since you

need a little headroom in case of overshoot.

A3: Correct Phase (same scanner speeds). The circle

should be circular, not elliptical or pulled to one side.

This is easiest to do when your scanner mirrors

are the same size. Unfortunately, some laserists have one mirror smaller

than the other, so the scanner with the smaller mirror can go faster. There

is no point to this. Diagonals will distort, and images will look different

as they rotate.

You want both scanner mirrors travelling at the same speed and with the same

response, so use the same size mirrors. As a bonus, this means you only have

to stock one mirror size.

A4: Correct XY Orientation. The "Y" should be

at the top; the "X" should be at the right.

If your scanner amp has invert switches, use these

to get the correct orientation. You can also use controls in your console or

computer software, but the best place to get the orientation right is in the

scanner amps (if possible).

A5: Correct Gain. The outer box shows the limits of the

scanner.

As discussed earlier, set the maximum scan size

for your screen, before doing final tuning.

A6: Correct Centering. The "+" marks the center

of the screen.

"B"

Tests: Blanking alignment

These tests were originally developed for

scanner (galvo) blanking. They can be used for adjusting any type of

blanking.

If you software offers this feature, adjust the blank timing or blank shift

slider to get the blanking point B1 roughly correct. Then, adjust the gain,

offset and damping of your blanking device (if you use scanner blanking).

B1: Correct Blanking Speed. The upper and lower

horizontal lines meet at the small vertical line.

B2: Correct Blanking Damping. Adjust blanking damping

(if you have scanner blanking) so the two horizontal lines are equally

spaced from the small vertical line.

B3: Correct Blanking Gain and B4: Correct Blanking

Bias. The fifth dot in this group should be barely visible; the sixth dot

should be completely blanked. Also the lines at B1 should approximately meet

at the vertical line.

This is only for those using Laser Fantasy of

similar pulse-width modulation scanner techniques. Most AOM and PCAOM

systems can show the sixth dot with no problem. A few AOM or PCAOM systems

may have built-in filters that emulate the slow rise and fall of scanner

blanking. If so, the B3 test should be used to fine-tune the filter.

At slow speeds, (lower points

per second) the circle remains outside the square.

At the proper, or rated, speed,

the circle must be just inside the square – it should touch the midpoints

of the square's sides, and it should remain circular (not oval or tilted).

At faster-than-rated speeds, the circle will be smaller than the square.

Other Considerations

It can not be stressed enough: Although you tune to the

ILDA test pattern at 12K or 30K, you do NOT have to project your images at

this speed. You probably will set your scanning speed slower, for example to

8K of 30K. Otherwise, you'll be putting too many points at sharp angles and

corners.

Pangolin suggests that you pick a standard scanning speed and stick with it.

Your choice of speed will be dictated by the galvo/amp combination you own.

A standard speed makes it easier for you, especially of you trade with, or

purchase frames from others using the same speed.

If you have other test patterns, such as the ubiquitous Laser Media pattern,

they may not look as good at the 12K or 30K speeds. If so, you can use these

test patterns to help determine what your everyday scanning speed should be.

It may seem obvious, but there are no differences between computer graphics

systems when it comes to single-frame output such as test patterns. If

software A shows the ILDA test pattern as 12K per second, software B will

look the same when showing that frame, at that speed, on the same projector.

In fact, for any given frame (e.g., set of points) and speed, all systems

will output identical points. This is how you can tune the same as a

colleague across the country.

Some software systems don't provide the scan rate in points per second. This

is unfortunate, since there is little reason to tune to the ILDA 12K or 30K

standards if you don't know how fast you're running. Use an oscilloscope or

ask your vendor to determine your absolute point rate. If your system uses

the older measurement of microseconds per point, the formula is: 1/sec. For

example, 80 microseconds is .00008 sec. Using the formula, this is 1/.00008

or 12,500 PPS. The ILDA 12K speed is 83 microseconds per point.

The theory behind the circle-and-square tuning is that the square has many

points while the circle has a few. The square will hold it's shape at fast

speeds, but the scanner/amp system has trouble with the circle. If scanning

systems were perfect, then the circle would be larger than the square -- the

way it was digitised. But since the scanners don't have a perfect response

the standard is arbitrarily set to have the circle be the same size as the

square. The sizes are not necessarily setting anything exact (such as a 3 dB

roll-off pint); they are mostly serving as a fast reference standard for

in-field tuning.

The ILDA Test Pattern is not the ultimate testing method. Pangolin believes

that a set of scanner test frames, each optimized for a particular feature,

is best. However, the ILDA Test Pattern is a good single-frame pattern, and

of course, is the only reference standard in the industry. While you might

be able to get some performance improvement using other patterns, smaller

angles, etc., it is better to be not quite perfect but to be compatible with

the rest of the industry.

Thanks to Casey Stack, ILDA Technical Standards

Committee chair who provided Laser Fantasy's documentation on their test

pattern (on which ILDA's is based). The A and B notation and structure have

been taken from that document.

Download

a copy of the ILDA Test Pattern [10 Kb]

Download a

copy of the ILDA B test pattern [11 Kb]

NOTE:

Since this article was written, ILDA has developed

a second test pattern for use with 30K scanners,

and has published a document that details the

tuning procedure in more detail. See the ILDA

Test Pattern article.

DISCLAIMER:

Some of the information in the Backstage area is provided by the persons or

companies named on the relevant page(s). Laser F/X does NOT endorse or

recommend any products/services and is NOT responsible for the technical

accuracy of the information provided. We provide this information as a

service to laserists using the Backstage area.

[

Introduction - System

Design - Scanning Systems

- Support

Equipment - Laser

Graphics - Show

Production - Pinouts ]

|