|

Home Page >>> Backstage Area >> Laser Hobbyists > Hobby Archives - 60X Fan Mount |

|

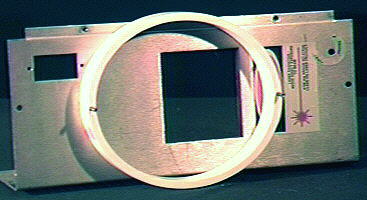

60X Fan Mount

This page was contributed by Mark Schweter schweter@mail.bright.net

Introduction This project was the result of a need for a "quick-fix" fan interface for my new 60X head. Previous experimentation by Steven Roberts, and myself, had resulted in mounts with a less than "professional" appearance. The design considerations were: A clean finished appearance, L.Michael Robert's information on fan selection and Karl Rothweiler's report of an "official" fan riser he had seen.

Parts & Fabrication |

| Fan | Model No. | AC volts | Watts/Amps | Rotron Part No. | Newark No. |

| Major | MR2B3 | 115V | 31 / 0.26 | 028245 | 81F8113 |

| Major | MR77B3 | 230V | 30 / 0.14 | 028309 | 44F916 |

| Patriot | PT2B3 | 115V | 31 / 0.26 | 028254 | 81F8114 |

| Patriot | PT77B3 | 230V | 30 / 0.14 | 028312 | 44F915 |

The fans can can be obtained world-wide from Newark Electronics and it's affiliates. (I bought mine from a local electronics surplus store.) Also obtain a suitable grille for mounting on the fan. I also purchased a fan-to-cord connector for ease of assembly.

Mount:

6" PVC sch40 pipe (sch80 will have

double the wall thickness). Sawn into a 1" [25 mm] section. File the

pipe section smooth and flat on edges so that it will mate to the lid and

fan.

Drill two holes through the pipe section 180 degrees

apart large enough to pass 6-32 screws. With a 1" [25 mm] section of

pipe, you will need 1.5" [38 mm approx.] screws with nuts and lock washers.

Paint or finish as desired (Ours are flat black to match the

fan).

Assembly:

Position mount on lid so

the greatest area of the blades is over the exhaust port of the laser head

as shown in the picture above.

Mark the positions of the screw holes and drill two holes

to match in the laser head cover (remove burrs and rough spots from the

holes).

Once the fan is mounted, make SURE the bolts clear ALL

internal laser parts and DO NOT touch ANY portion of the riser or the

interior of the laser head.. WARNING: Failure to do so WILL destroy your PSU

and your 60X head!!!

Mount fan so air is EXHAUSTED from the riser opening.

(fan airflow indicator pointing away from head - the air blows upwards).

Fan Power

There are 4 wires coming

out the side of the head, usually going to a 4 pin connector. Two of these

carry 110 volts (250 on European 60Xs) and two of the wires are part of the

start interlock circuit.

Connecting the 110 AC wires to the

start Interlock wire will result in fatal damage to the power supply and

head.

The correct procedure is to use a ohm meter to find the

leads. Clip one lead of the ohm meter onto a wire sticking out of the fan

connector, take the other probe and go to the pins of the 22 pin connector

on the side of the head.

If the wire connects to PIN 16 or PIN 20 as indicated by continuity it's 110 AC (or 250 on European 60Xs) power to the fan.

If the wire has continuity to PIN 18 or PIN 21 it's an INTERLOCK WIRE, The laser will not start if the interlock wires are not connected.

Continue testing until

you have identified all four wires as either power or interlock wires.

16 and 20 AC to fan - 18 and 21 Interlock

NOTE: On 60X lasers with interlock switches under the cover, the switch must be depressed (on) for you to get a reading on the meter when testing interlock wires. The thermal switch clamped to the tube must also be in proper working order (normally closed) in order to get a reading.

The factory put a 4 pin connector on the fan for a good reason. By putting a loop of wire on the fan side of the connector to close the interlock circuit, they provided a means for confirming a fan is attached. It would be prudent for the laserist to do so as well, especially if you use a detachable fan. A 60X tube will only survive without damage or change in gas pressure for about about 1 minute when operating at 10 amps without a fan.

WARNING: Incorrect wiring WILL destroy your PSU and your 60X head!!!

Most of the information and ideas in the Hobby Archives have been contributed by hobbyists and experimenters. If you have any comments or ideas to share, please contact us by E-mail.

DISCLAIMER: Some of the information in the Backstage area is provided by the persons or companies named on the relevant page(s). Laser F/X does NOT endorse or recommend any products/services and is NOT responsible for the technical accuracy of the information provided. We provide this information as a service to laserists using the Backstage area.

[ Introduction | Hobby Archives | Hobby FAQ | Laser Construction ]

|

©

1996-2008

Laser

F/X International and LaserFX.com - All rights reserved. |

|